QEMSCAN

The QEMSCAN facility.

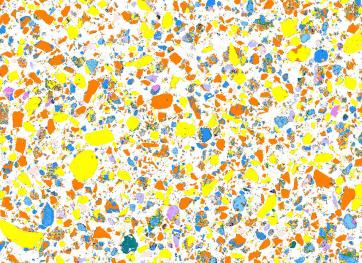

A color-enhanced particle map of a sample. Each color represents a different mineral.

QEMSCAN® uses advanced electron beam technology and combines this with high-resolution backscattered electron (BSE) imaging and two energy dispersive spectrometers (EDS). The components are then integrated using electronic control systems and the unique iExplorer software suite to provide a comprehensive tool capable of identifying most ore- and rock-forming minerals on a micro-scale in just milliseconds.

The EDS and BSE data are collected at user-defined stepping intervals across the sample (typically 1 – 30 micrometers). The analyses at each point are correlated with a library of mineral/phase identifications such that each data point is mapped as a specific mineral or phase. The output of the analysis is a false-colored image with associated quantifiable data. The iExplorer software suite not only controls the operation of the hardware but also analyzes the data generated to provide information about the chemical and mineral composition of the sample, as well as the textures, mineral abundances, mineral associations, grain sizes, liberation characteristics, surface exposures, and shapes through the analysis of digital mineral maps.

QEMSCAN has the ability to handle a wide range of sample types, usually set in epoxy, as blocks or thin sections, and even set on conductive tape. It can be used for analyzing almost anything from core samples, offcuts, and rock chips to soil, manufactured products, and dust.

Service Applications

Related Capabilities

Contact Hazen

Main (303) 279 4501

Fax (303) 278 1528

E-mail / Directions

Submit RFP